Leading Manufacturing Companies – Bharat Bijlee

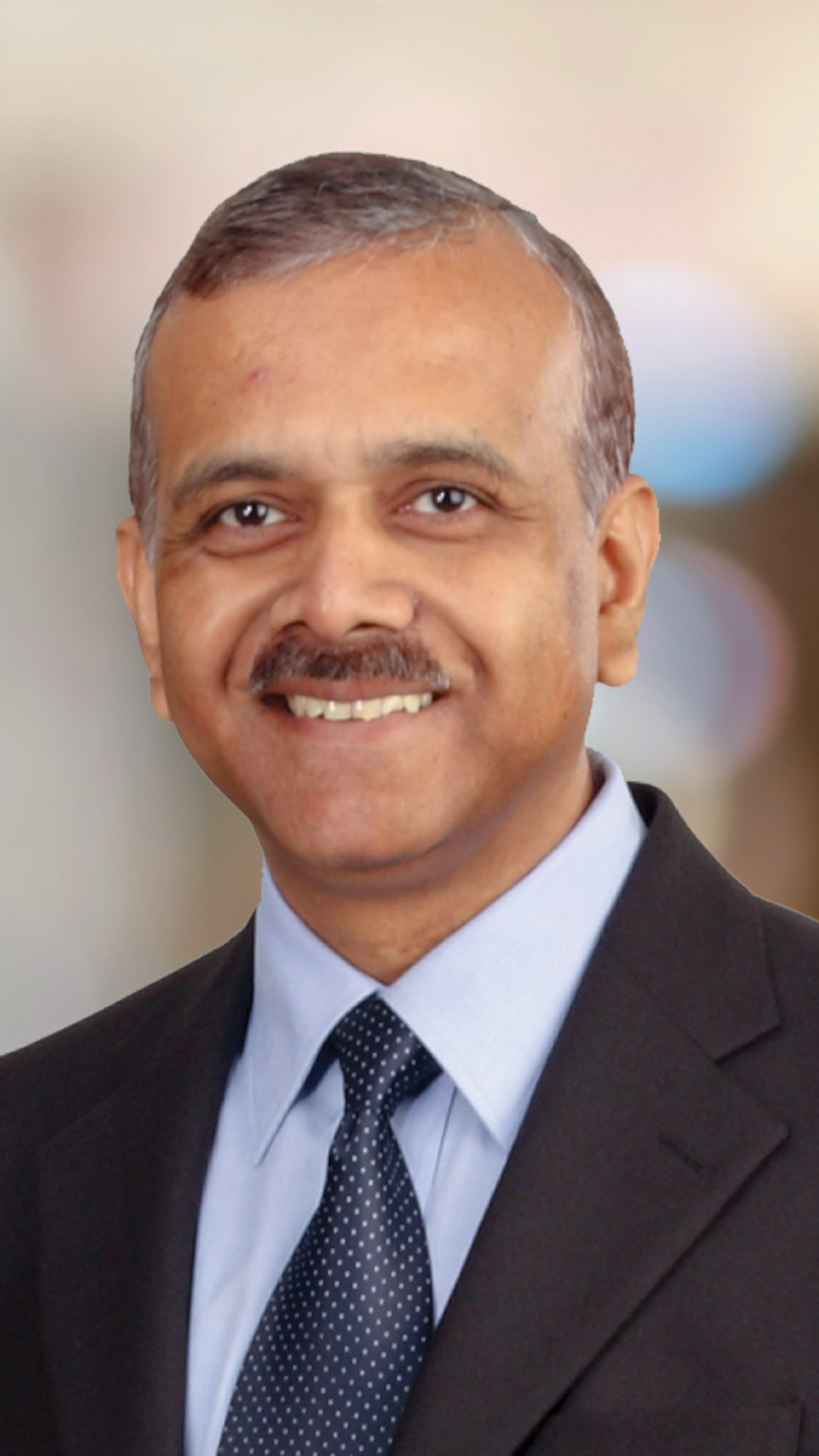

At Bharat Bijlee, the Motor Division works on the principle of ToC (Theory of Constraints). This means that they take a holistic or global view of the business, and that all functions and processes collaborate closely. The plant’s interaction with R&D and quality assurance is very close. “Order execution and new product development follow well defined methodologies, but we also need to address ongoing product improvement in a structured way; this can get triggered by value engineering or from field feedback, and loop closure involves the entire value chain from vendors to service providers,” explains Vakharia.

Recently, by a government notification, the production and sale of any motors other than those designated and certified as energy-efficient was prohibited as of January 2018. This posed an enormous challenge, as production of energy-efficient IE2 and IE3 motors had to scale up from 15% to 100% of volumes. “We were able to manage this transition only by the plant working very closely with R&D and supply chain, as well as the marketing teams,” says Vakharia.

In the last two years, there has been more pressure than ever on ensuring on-time order fulfilment, and on improving productivity. However, Bharat Bijlee has been able to improve assembly line efficiencies by: reviewing production processes and eliminating activities that were redundant due to new developments; eliminating bottlenecks to improve material flow; full kitting on assembly lines to ensure full line utilisation to their installed capacity; and providing infrastructure for increased production volumes. This has helped to reduce costs as well as to improve inventory turns.

-(3).jpg)

.jpg)