Leading Manufacturing Companies – BASF

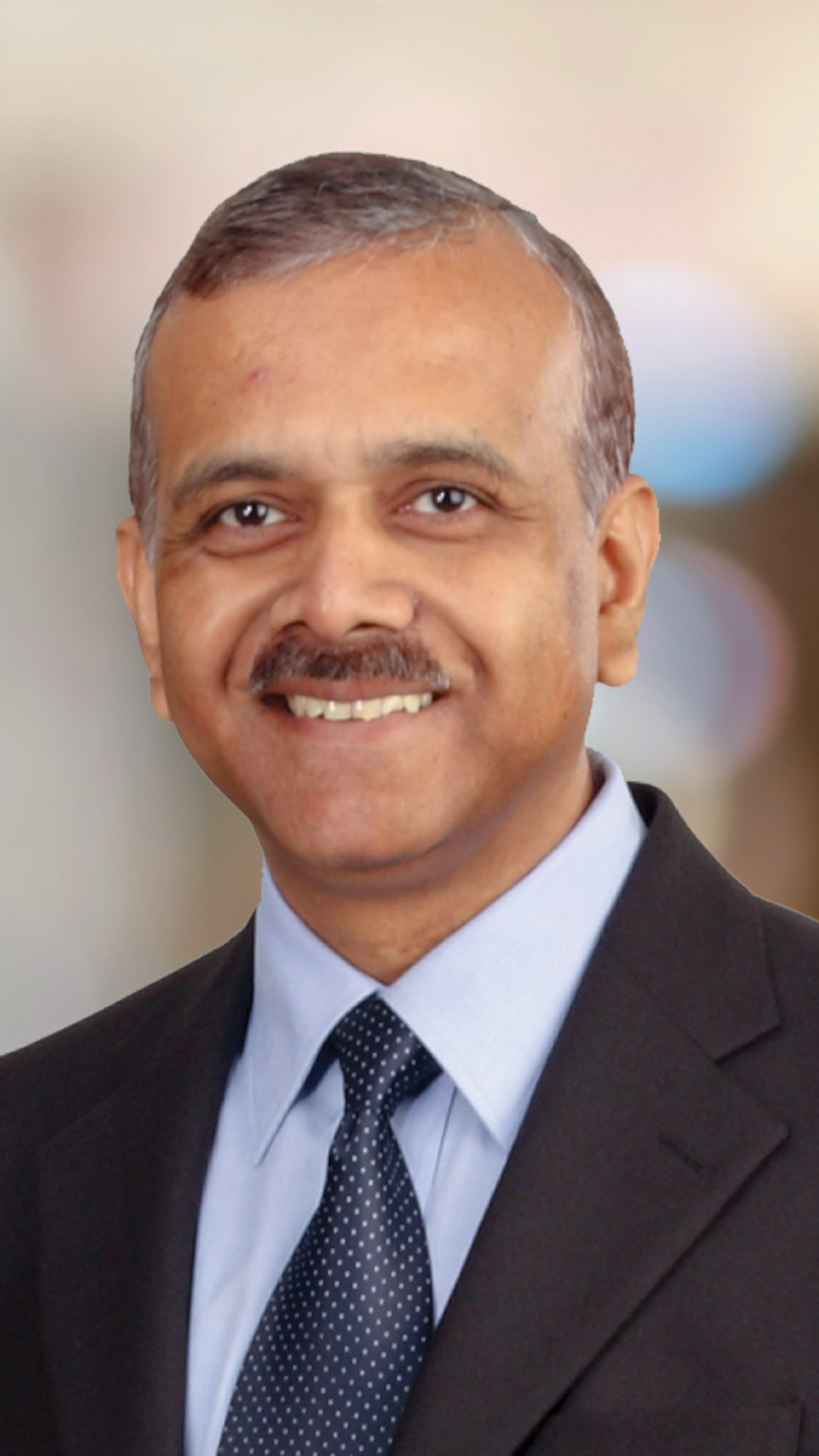

The phrase ‘change is the only constant’ fits perfectly when we consider the developments that the supply chain industry has been through in the last few years. Today, information is available at the fingertips with the internet becoming more widespread, ever evolving bandwidths and reducing costs. This has led to a knowledgeable and aware consumer base for every organisation. As a result, supply chains today need to be integrated and agile. Gone are the days when organisations in a value chain would work in silos. “With the advent of technologies like block chain, the industry must move towards integrating the value chain to provide a sustainable output for the end-consumers. Supply chains around the globe are under pressure to evolve and perform, keeping a holistic approach in mind,” confesses Matthew.

Also, GST has had a radical impact on the way businesses used to work with the numerous indirect taxes and legal laws. “Due to GST, we can now consider having tailored supply chain models that suit customer needs and help in better integration with their supply chains. Eliminating the stock transfer benefits also helps in direct dispatches to customer locations,” says Matthew.

The implementation of GST takes away the tax distortion from the supply chain. For example, the decision to locate a factory or warehouse will now be based on where it makes most sense from the value-chain perspective. Overall, GST helps in improving the logistics scenario in a country where logistics remains a major unorganised sector, along with opening new gates for increasing export of goods from India.

-(3).jpg)

.jpg)