Leading Manufacturing Companies – Blue Star

Supply chain is the most dynamic function in manufacturing, today, and treated quite seriously at Blue Star. After all, with customer preferences becoming varied, customised and ever changing, the whole supply chain needs to be agile and flexible.

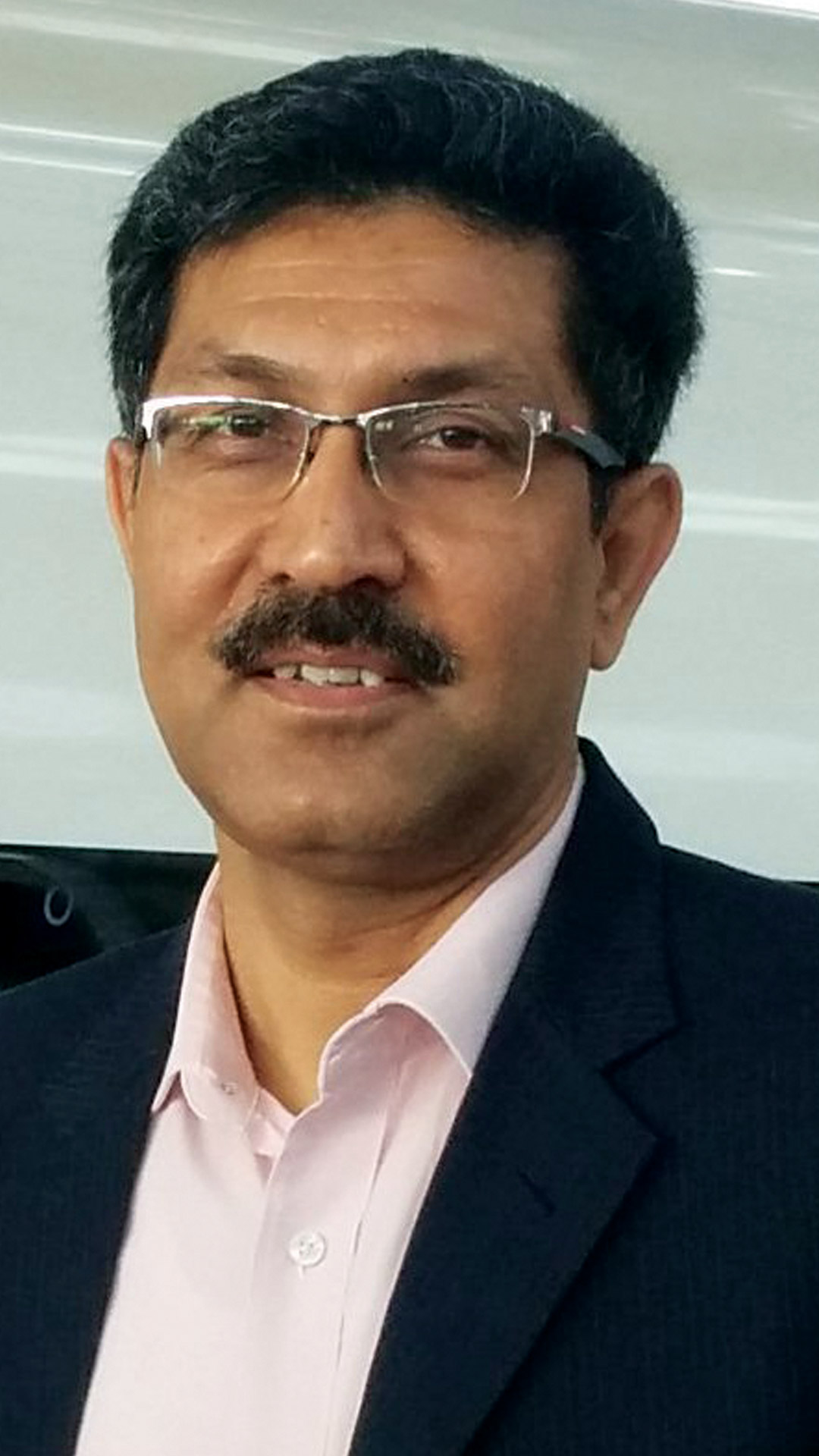

“This also requires access to data such as customer specifications, design, cost and material in stock across the value chain, in order to deliver the goods or services at a competitive price, on time,” says Roy.

And this is made possible only through integrated data management and real time capturing, monitoring and analysing data. Vendor portals have become the order of the day with fully integrated P2P processes. While it is easy to capture data through various integrated software, analysing and interpreting data has always been a challenge. “Very shortly this skill set will be in demand. Ability to forecast demand, supply constraints and commodity movement have become key factors for success. As a result, supply chain is increasingly becoming a differentiating factor in an organisation. The good thing is that organisations have started recognising this,” believes Roy. He advises that in order to maximise the benefit of GST, organisations need to reexamine their sourcing, warehousing and, in the long run, even their manufacturing strategy.

-(3).jpg)

.jpg)