Leading Manufacturing Companies – Tata Advanced Materials

In 2017, the biggest incentive for TAML is to invest on capital equipment and skill building since the aerospace & defence industry has seen growth in India. However, the main challenge was to encourage skill building for the employees so that the company could see a ramp up in volumes and also consider various new products. This was in addition to the cost reduction initiatives that customers were looking for to make their supply chain more competitive and pass on benefits to the OEMs.

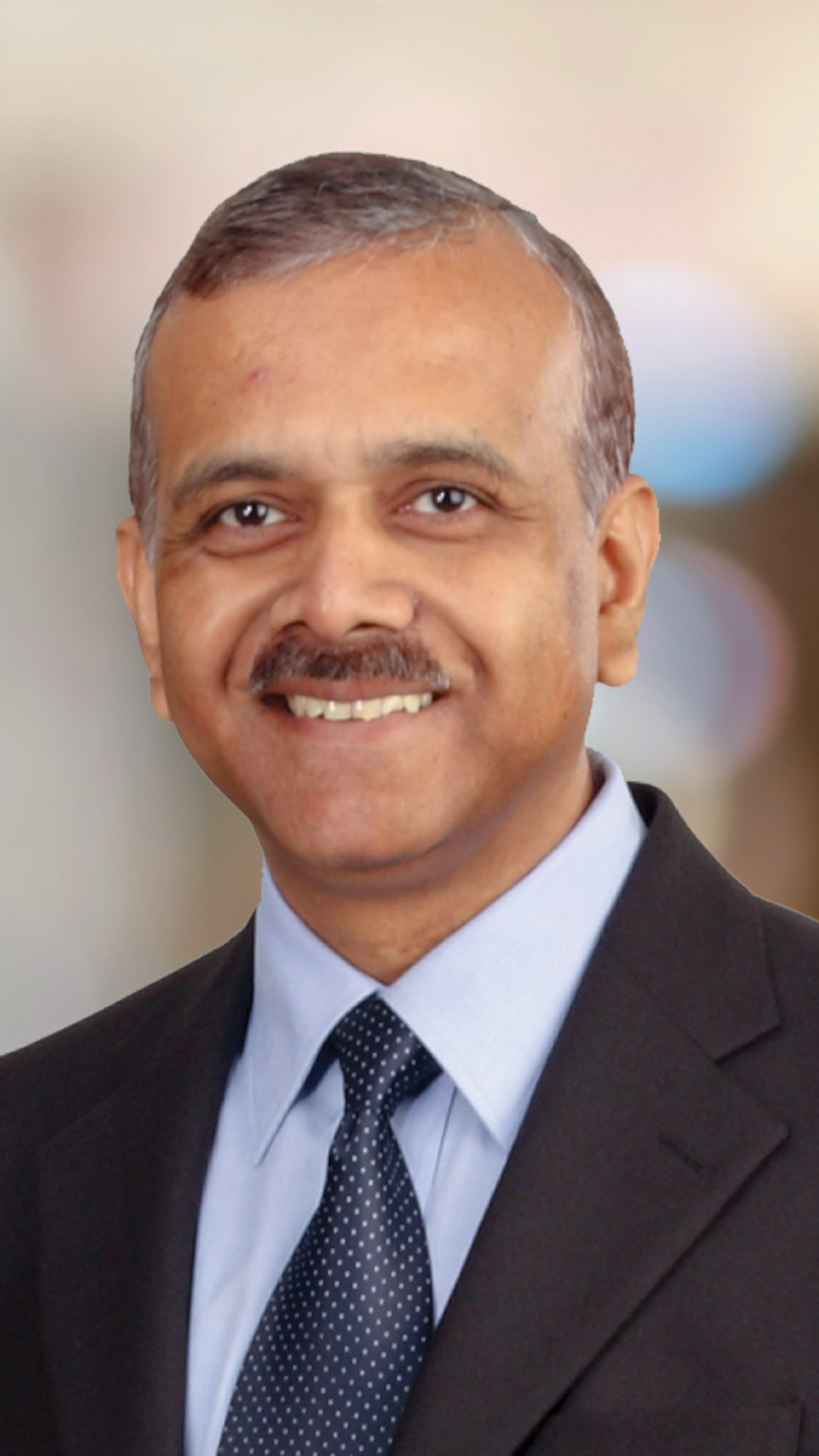

Going forward in 2018, the main thrust will continue to be towards making TAML leaner and more competitive and building up skills towards newer technologies. “In addition, implementing digital initiatives on the shop floor towards automated processes in planning, scheduling and monitoring will help us drive down costs by improving efficiencies. We have implemented Automated Planning and Scheduling software across various programmes in our shop which is showing results in meeting customer delivery schedules,” says Mukherjee.

The company has already started lean implementation in its shop floor through value stream mapping, identifying wastes and paring costs. It wants to act more on these techniques and implement them through dedicated teams. Motivation and retaining the talent pool will be another key initiative. The aerospace industry is looking for shorter time frame to deliver results and this will help agile companies to grow faster in this domain.

-(3).jpg)

.jpg)