Leading Manufacturing Companies – Dr Reddy’s Laboratories

.jpg)

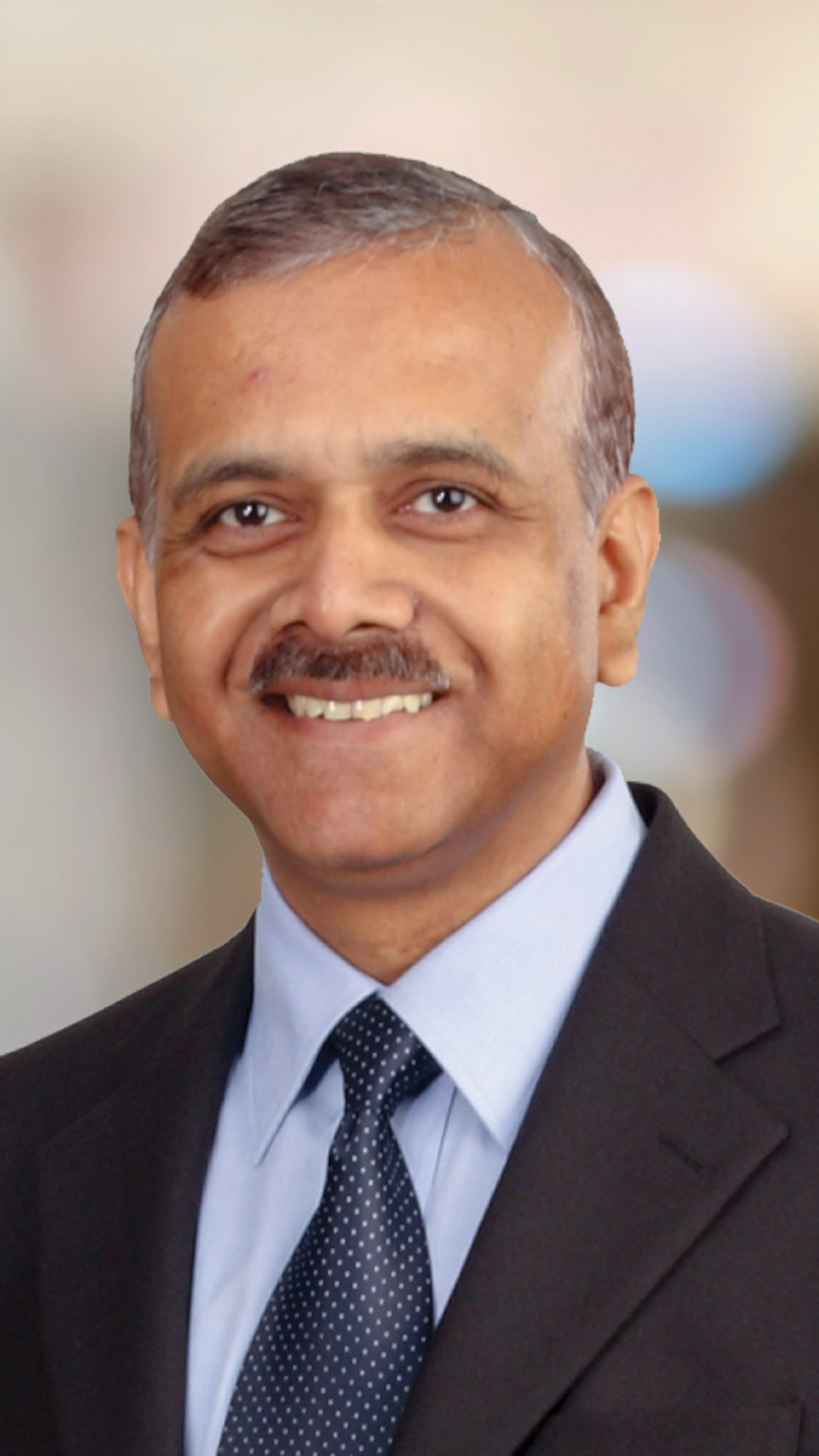

Over the last couple of years, there are multiple changes in the supply chain function, owing to a change in market dynamics and regulatory requirements.

Firstly, it has become paramount to launch differentiated and innovative medicines in order to cater to the growing therapeutic needs. Hence, the entire project management of launches is gradually shifting to supply chain in order to bring agility and speed in execution to stay ahead of the competition.

India has a high dependency on China to import basic chemicals and raw materials, however, with the growing instances of supply unreliability and cost escalation, there is a shift in focus to source locally. Increased focus to enhance the quality and capability of external manufacturing partners is seen.

There is also an immense focus on attracting and retaining the best talent in an increasingly competitive market. Outsourcing transportation and warehousing operations to 4PL logistics providers is happening. Finally, there is better utilisation of available technology to streamline and simplify processes.

“The GST transition has been quite challenging for the industry, considering the various changes in the IT system, tax-compliant invoice formats and pricing structure, treatment of closing inventory and stock returns, purchase from loan licensing locations as well as the training needs of employees and partners,” says Garg, adding that GST is still evolving and the Government will make the process simpler and more robust in time to come.

-(3).jpg)