Leading Manufacturing Companies – Henkel Anand India

At Henkel, the functions of R&D, quality and supply chain, are well integrated into the plant structure, which necessitates daily interactions for collaboration.

The quality manager works very closely with the plant manager right from the morning meeting, to the quality walk around at site, to identifying quality punch points, to support in problem solving, jointly addressing customer and supplier complaints, training, FMEAs and much more. Similarly, with regards R&D, the nature of Henkel’s products is such that change is a constant. New product introduction has several gates before a product is commercialised; moreover, any small change is brought about through the Management of Change process. Hence, for a plant manager, collaboration with the R&D/ Product Development function is a must to ensure success. As far as the supply chain is concerned, Henkel has been in the forefront of digitisation. Their advanced supply and demand planning tools are linked to the ERP system. This allows automation and proper planning.

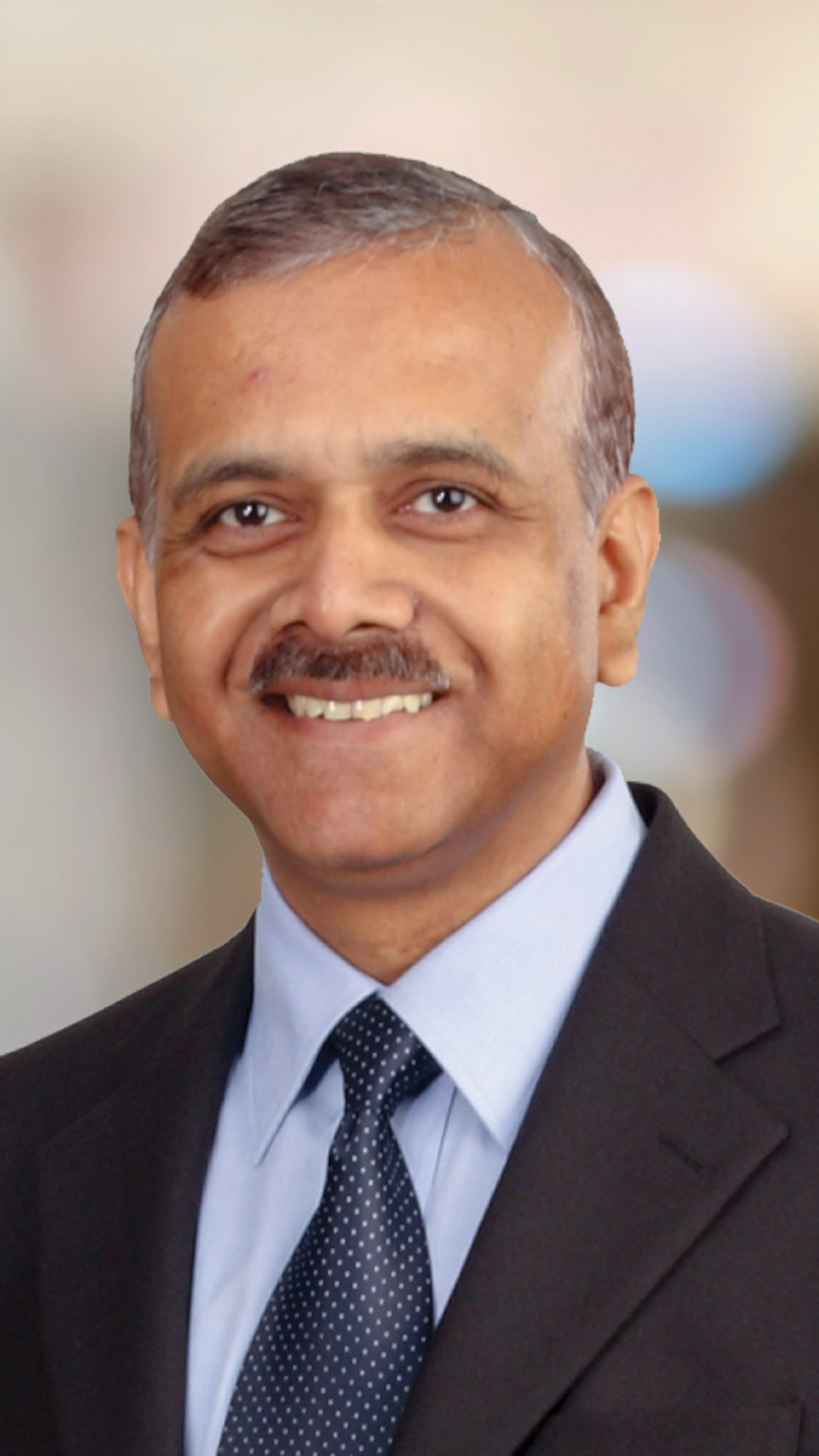

“The last two years has seen huge strides made in the areas of safety, quality and productivity. Unit cost of production has been one of the most important drivers to remain efficient and fund growth. With so many Henkel factories manufacturing the same products, there has been cut-throat competition to be the benchmark in terms of unit processing cost. The concept of one global supply chain will ensure that each plant is fully utilised as all markets will want products with the lowest cost of production,” admits Aggarwal.

-(3).jpg)

.jpg)