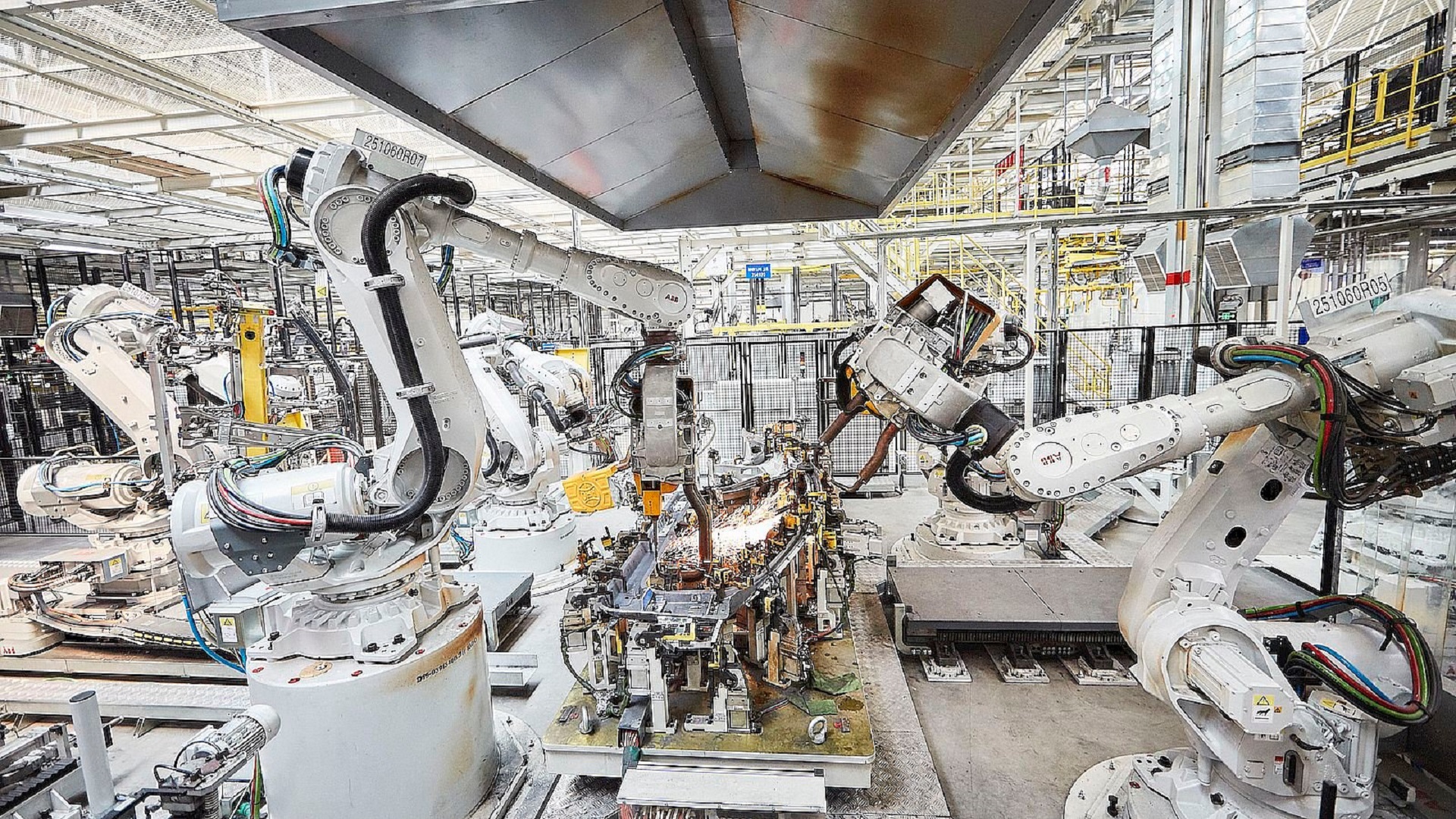

In a recent analysis, Frost & Sullivan found that the global industrial robotics market will reach revenues of $38.3 billion in 2024 from $22.2 billion in 2020 at a CAGR of 12.2%. Although the industry was curtailed by the COVID-19 pandemic and uncertainty in the automotive business, the global consulting firm said that the rising demand from other high-growth sectors is expected to propel it over the next five years.

It said pharmaceuticals will be the fastest-growing segment, with a CAGR of 17.2% from 2019 to 2024, reaching $3.33 million by the end of the forecasted period, followed by food & beverage (F&B) and electrical and electronics, expanding at 15.8% and 15.1%, respectively.

It said Asia-Pacific region will continue to dominate the global industrial robotics market, and revenues are estimated to top $25.08 billion by 2024, with China, Japan and South Korea driving progress. The European region is the second most important, propelled by the automotive industry and Germany—the fifth-largest country globally for industrial robotics. North America’s ongoing trend of production automation and keeping all manufacturing operations in-house puts it in the third position, with forecasted revenues of $6.19 billion by 2024.

“The global battle against the COVID-19 pandemic has proven to be a strong use case for industrial robots, which helped assure business continuity,” said Nandini Natarajan, Industry Analyst, Frost & Sullivan.

While 2020 witnessed reduced investments in robotics, she said the demand for industrial robots will rise sharply from 2021 on. “The introduction of low-cost robots and innovative business models such as Robots-as-aService (RaaS) are expected to drive demand from small and medium enterprises (SMEs).”

Natarajan points out that collaborative robots (cobots) are experiencing rapid market growth thanks to their utility, ease of installation, and consistently decreasing price, making them an affordable and viable solution for a wide range of applications. “It will be the fastest-growing segment by 2024, recording a CAGR of 32.8% (2019-2024) and reaching $1.78 million in global revenues. Advances in 5G and edge computing will be instrumental in equipping cobots with improved flexibility and easier implementation.”

For further opportunities, she suggests market participants should explore these strategic recommendations:

Embedded vision and machine learning in robotics: Embedded systems need to be lightweight, consume less energy, and be adaptable to be retrofitted/integrated with any robotic system. Manufacturers need to integrate advanced supportive technologies such as 3D perception and deep machine learning to enable new machine vision applications.

Smart robot grippers for safe collaboration with human workers: Robots have become more collaborative with human workforces instead of replacing them, as was the case before. Therefore, there is a need to design robot grippers that are more collaborative and safer. End-of-arm tooling (EOAT) providers will need to develop robot prototypes with advanced sensors that can detect human workers’ presence and movement.

5G and edge AI for robotic independence and flexibility of real-time applications: While 5G will provide benefits such as low latency and on-the-go decision-making, edge-based AI will enable robots to carry out data processing on the machine without data traveling to and from the cloud. There will be a huge demand for secure local data processing closer to the robot.