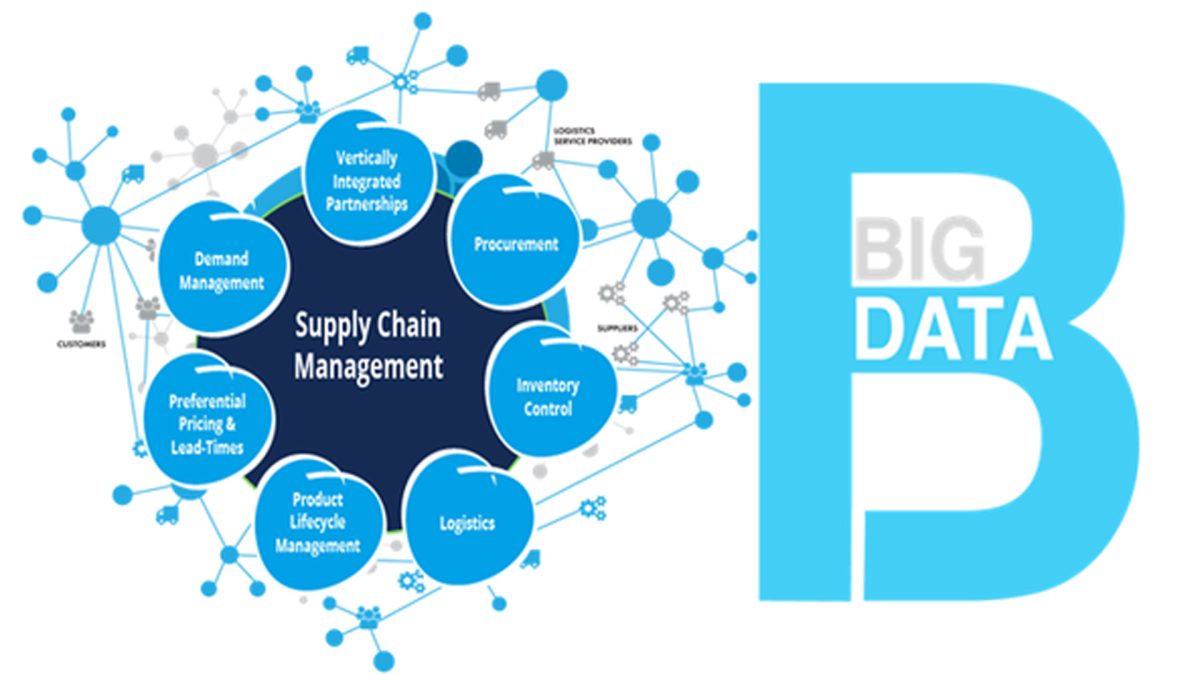

Data analytics has become an integral part of supply chain management, helping companies to make informed decisions and optimize their operations. Supply chains generate massive amounts of data, from inventory levels and production rates to shipping schedules and customer demand. With data analytics, companies can extract valuable insights from this information, enabling them to forecast demand, identify potential bottlenecks, and improve their overall efficiency. By leveraging data analytics, companies can reduce costs, increase productivity, and enhance customer satisfaction, all while gaining a competitive advantage in the marketplace. In today’s fast-paced business environment, data analytics is essential for supply chain management success.

In conversation with Rakesh Prasad, Senior Vice President, Strategy and Solutions, Innover, about the ‘Data Quality Framework’, which has been solving major problems for manufacturing and logistics businesses in India.

Can you give us an overview of the manufacturing sector and why there’s a growing interest in adopting digital technologies to achieve operational excellence?

According to recent reports, the manufacturing market is projected to reach US$244.50 billion in 2023, with an expected CAGR of 8.36% from 2023 to 2028. This indicates a growing demand and potential for value-added manufacturing activities involving processes such as customization, assembly, and packaging that add value to raw materials or semi-finished products. However, today’s manufacturing and logistics organizations face many challenges that impede their ability to operate at peak efficiency. These challenges encompass fluctuating demand, sub-optimal inventory management, production lags, unplanned capacity allocation, eroding costs, etc. A real-time holistic view is crucial to track and optimize the multitude of moving parts from demand to fulfilment to meet production and delivery goals effectively.

Integrating technologies like Analytics, AI, automation, and robotics can enable manufacturers to streamline their processes, minimize errors, and optimize resource utilization, leading to operational excellence. These digital technologies enable advanced quality control through real-time monitoring, predictive analytics, and machine learning – detecting defects early, improve product quality, and facilitate swift data collection for agile decision-making. By analyzing data from sensors, machines, and production processes, manufacturers can gain intelligent insights into asset health, last-mile configuration, shipment lifecycle, load movement and much more. This allows them to confidently overcome challenges and outdo the competition in a rapidly evolving playing field.

What challenges do businesses in the manufacturing sector face when it comes to data quality? How does accurate and consistent data quality impact decision-making across industries?

Manufacturing companies generate colossal amounts of data from disparate sources, such as production data, machine sensor data, equipment and maintenance data, distributor and partner data, real-time sales and customer data and more. However, the real challenge lies in sifting through these disjointed, siloed data sources to uncover valuable insights that can optimize manufacturing and field operations and elevate customer experiences. Moreover, the data collected may be incomplete, inconsistent, or non-compliant with various policies. To keep the engines running and facilitate speedy analysis of this heterogeneous data, manufacturers must ensure their data meets all the standard requisites and qualifies as ‘Good Quality Data’. They need to employ modern data analytics tools to improve the data quality, unlock valuable insights, and achieve unparalleled levels of efficiency, quality, and innovation that set them apart in a fiercely competitive marketplace.

Further, by incorporating AI-ML-powered advanced algorithms and data validation techniques, manufacturers can draw valuable real-time insights into demand and traceability to keep production on schedule, mitigate supply chain disruptions and stay on top of ever-evolving market conditions. With reliable and precise data, businesses can identify potential points of failure in advance, minimize the impact of any unexpected events, and make data-driven decisions that enhance agility and resilience in the face of change.

Innover has developed a Data Quality (DQ) Framework. Could you elaborate on what it is and how it can improve data quality for businesses using AI/ML?

The suite of Data Engineering and Advanced Analytics solutions offered by Innover includes a comprehensive Data Quality framework that ensures critical data sets’ accuracy, consistency, and completeness. Our Data Quality (DQ) Framework empowers organizations to proactively identify high-impact data-related issues across multiple sources to progressively clean and improve the data quality within 6-10 weeks. Powered with a pre-built AI & ML based data validation layer, the solution helps businesses automate required checks and balances and identify more than 80% of data sources/processes that are erroneous, inconsistent or redundant. The framework generates a robust scorecard, enabling organizations to measure and benchmark the quality of their data against industry standards and peers – providing a clear picture of an organization’s current data health and the right steps to incorporate to build a trusted, confident data foundation.

Innover’s proprietary Advanced Analytics platform LEAPTM , has been at the forefront of accelerating the data journey, from when it is captured to the eventual insights it offers for informed decision-making. LEAP can combine large volumes of structured and unstructured data from multiple internal systems and external data sources. As the next step, it creates a reliable data pipeline suitable for analysis by ensuring the available data is complete, accurate and secure with a robust audit trail, tamper-resistance and adherence to Enterprise data standards. By applying statistical and Machine Learning algorithms, LEAP’s Analytics Engine helps to turn this data into powerful business insights. LEAP can expedite enterprise-wide data-driven decision-making through its business insights layer by providing on-demand, role-based secure data access via multiple consumption tools and conversational AI. Finally, the top business services layer can help enterprises apply these insights to drive tangible outcomes in the fastest turnaround time.

Can you walk us through a success story or case study where Innover’s solutions were used to address data quality issues in the manufacturing space? What was the problem and how did Innover’s solutions help solve it?

A leading North American elevator manufacturer wanted to mitigate frequent breakdowns and significantly save manpower. However, they were struggling with a high volume of unscheduled service calls due to elevator breakdowns, which increased service costs and disrupted technician schedules.

Innover leveraged LEAP’s AI-powered predictive maintenance model and Microsoft Azure’s cutting-edge offerings suite to build a comprehensive cloud-based elevator monitoring system. We connected all the heterogeneous data sources (service scheduling, repair reports, utilization rates, downtime summary, energy consumption, etc.) into a unified interface. We created rich datasets and automated reports to drive data-driven pre-emptive decision-making. Intelligent System Service built by Innover provided a 360-degree view of more than 250 elevators and generated valuable insights to enable proactive action for predictive maintenance. The solution helped the client to efficiently allocate their manpower for addressing breakdowns. At the same time, the system’s condition-based monitoring ensured proper maintenance of all connected elevators, leading to a significant reduction in associated service costs. The impact delivered was impressive, with a 78% reduction in unplanned downtime, $120k savings per quarter, and a 33% improvement in Service Level Agreement adherence.

What sets Innover apart from other companies offering data quality solutions in the market? How do you ensure your solutions stay up-to-date with the latest technological advancements?

Innover’s Data Quality Framework helps build confidence in every data byte, across all sources, for all users, enabling organizations to propel toward data-driven supremacy and success quickly. The framework helps organizations identify more than 80% of contributing data errors and outliers using AI/ML-based accelerators. It also allows them to objectively and honestly measure their data quality and assess how their business “stacks up” against the standard or their peers. Our DQ solution is not just limited to master data quality management but also helps clients improve their transactional data quality.

Further, our Advanced Analytics platform, LEAPᵀᴹ, is at the forefront of accelerating the data-to-business outcomes journey, leading to accurate and relevant insights, faster time-to-insights, and reduced cost-per-insights.

What makes LEAP stand out in the market?

- 60+ pre-built AI models and accelerators – leading to high-speed data ingestion, insights and accelerated business value. Here are some of our Ready to use AI models for manufacturing: Resource allocation & optimization, preventive maintenance, Original Equipment Effectiveness (OEE), asset life expectancy prediction, shipment delay prediction, asset idle & response time insights – boosting efficiencies and ensuring an optimized network across geographies

- Modular, scalable and platform-agnostic framework – plug & play facility allowing ala carte models customized to client business needs

- Infused with Innover’s deep domain expertise and tech prowess – we have done this for multiple clients across multiple industries

- Closed-loop performance management across the data lifecycle – via the right KPIs and statistical evaluations to boost data quality and trust

- Self-funding analytics delivering 3x+ returns within 8-12 weeks

At Innover, we help our clients become connected, insight-driven businesses powered by cutting-edge technology and accentuated by experiences to deliver 360° impact and ROI-driven outcomes. Our Innovation Labs serve as a hub for creativity and collaboration, where we harness the power of new-age tech to turn our clients’ digital manifestations into tangible reality. Whether it is experimenting with Metaverse or enabling businesses to embrace intelligent process automation, we enable our clients to build compelling use cases that push the boundaries of innovation.

Can you speak to the scalability of Innover’s solutions? How do you work with businesses of different sizes and industries to implement your solutions?

As previously mentioned, our Advanced Analytics Platform, LEAP, is designed to be highly modular, easily scalable, and adaptable to any technology environment. This means that LEAP can be utilized at any stage of the analytics journey and seamlessly integrate with various technologies, helping businesses of all sizes to build tailored analytical solutions to drive success.

Our solutions have been successfully deployed across a range of industries, including Manufacturing, Telecom, Logistics, FMCG, Retail, BFSI, Hi-tech, and e-commerce. We leverage cutting-edge technologies such as IoT, Blockchain, AR/VR, Metaverse, and IPA, in combination with powerful data analytics, to deliver innovative solutions that drive business growth and enhance efficiency.

What’s next for Innover? Are there any new products or services on the horizon that you’re excited about?

We have recently launched a plug-n-play SaaS-based platform for non-profits to help them embrace digital transformation, accelerate their vision of integrated commerce, drive analytics-aided member and donor experiences and advance their missions.

We are dedicated to growing our analytics team and investing in Innovation Labs to stay ahead of the curve in adopting emerging trends in data and analytics such as AIops, MLops and generative AI solutions. Our innovative spirit drives us to experiment with the Metaverse, lead intelligent automation initiatives, and build game-changing products that resonate with customers.

We are betting big on LEAPTM and will continue to expand its suite of prebuilt models and algorithms across manufacturing and other industries – evolving its analytics capabilities, building more promising use cases and venturing into new markets and industries.