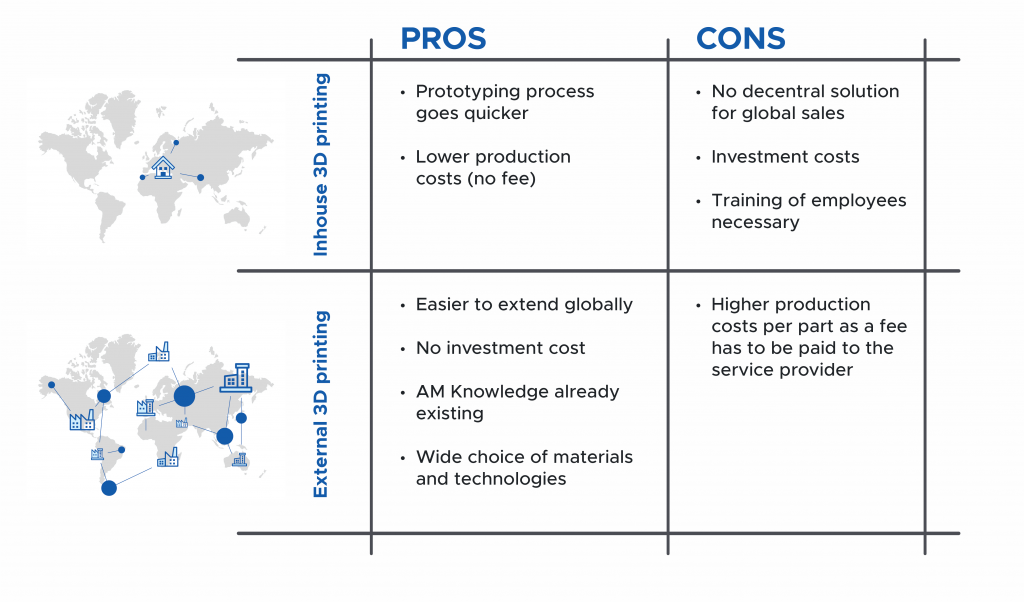

With increasing uptake of 3D printing, additive manufacturing, more applications emerge. In turn, more companies consider integrating the technology into their processes. With this, the question of whether they should outsource 3D printing or produce in-house arises. As with most business decisions, there is no simple answer and there are pros and cons for each option. However, the following six considerations should help in finding the right solution.

Location : If you only need to provide the parts within one country or region, having the printers centrally would likely be the best solution. However, if providing parts globally, shipping parts to the other side of the world is expensive, even without the ongoing supply chain disruptions. Engaging with multiple print farms or even with a 3D printing platform could be the better solution.

Design flexibility : When a product is still in the prototyping phase, parts need to be produced, tested, and sometimes redesigned multiple times. This is easiest and quickest when 3D printing is close to hand in-house, as there is less toing and froing and design changes can be implemented quickly. When outsourcing, it can take longer to make changes as there is typically an extra link in the chain and parts need to be shipped.

Scalability : To decide on the scalability of in-house and external 3D printing two factors need to be considered:

– Number of different designs. With the continually increasing number of 3D printing technologies and materials, the printer-material combinations are endless. If you plan to produce a large array of different products, this would most likely mean that they would be produced in different materials and printing technologies, and so multiple different printers would need to be purchased. In this case, outsourcing is the better solution to reduce complexity and investment costs.

– Number of parts. If large quantities of parts are needed, it might be preferable to outsource, to reduce complexity and time spent producing them in-house. Similarly, if only one or two parts are needed per week, it does not make sense to invest in a 3D printer. Ultimately, it’s about assessing your specific needs to ensure a return on investment.

Investment : While there are budget-friendly desktop 3D printers on the market, for certain parts, you might need high-end systems that require significant upfront investment. On top of that, maintenance, training and hiring of employees, and material procurement will contribute to the overall cost. If these expenses are not justified by production volume or innovational power, working with a 3D print farm or online production platform is likely to be more cost-effective.

Capability (Know how & Quality Assurance) : 3D printing differs highly from other manufacturing methods and there are several design and production guidelines you need to fulfill to ensure high-quality parts. This may not be a huge problem if you possess the internal expertise and resources, but if you are falling short in any of these areas then outsourcing might be the better option to ensure high quality parts.

Timeline : Setting up an internal 3D printing service will take time. The buying process and installation of 3D printers is a matter of weeks, however training or hiring of employees and setting up production operations is something that will take much longer. Again, this may not pose an issue in instances where time is not an issue, but if you are on a tight schedule, it might be worth considering external 3D printing.

Why not combine both solutions?

In some cases, combining both options might be the best solution. You produce certain parts in-house that can be handled by your own 3D printer, while you order the rest of the parts externally. This might sound like it needs quite some coordination, however, with a digital platform this would be very easy. Within your personal platform you can connect your own 3D printers, and can either select to print the parts in-house, or place an order and let the parts be printed externally by a 3D printing service bureau near to where the parts are needed.