STMicroelectronics a semiconductor firm serving customers across electronics applications, has released high-power modules for electric vehicles that boost performance and driving range. ST’s new silicon-carbide (SiC) power modules have been selected for Hyundai’s E-GMP electric-vehicle platform shared by KIA EV6 and several models.

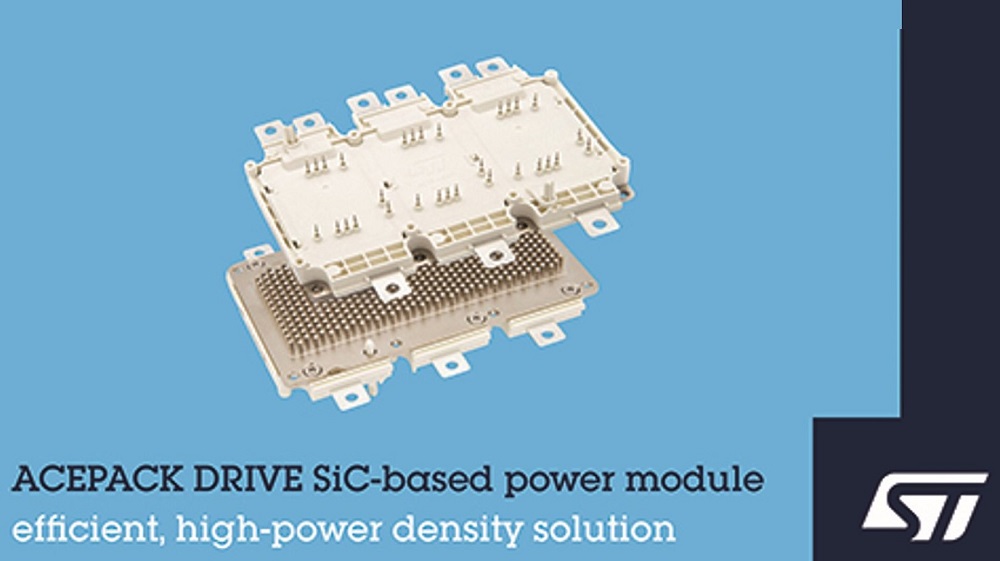

Five new SiC-MOSFET based power modules provide flexible choices for vehicle makers, covering a selection of power ratings and support for operating voltages commonly used in electric vehicle (EV) traction applications. Housed in ST’s ACEPACK DRIVE package optimized for traction applications, the power modules are reliable thanks to sintering technology, robust, and easy for manufacturers to integrate in EV drives. Internally, the main power semiconductors are ST’s third-generation (Gen3) STPOWER SiC MOSFETs, which combine industry figure of merit (RDS(ON) x die area) with very low switching energy and super performance in synchronous rectification.

“ST silicon carbide solutions are enabling major automotive OEMs to set the pace of electrification when developing future generations of EVs.Our third-generation SiC technology ensures the greatest power density and energy efficiency, resulting in superior vehicle performance, range, and charge time.”said Marco Monti, President, Automotive and Discrete Group, STMicroelectronics.

Hyundai Motor Company has chosen ST’s ACEPACK DRIVE SiC-MOSFET Gen3 based power modules for its current-generation EV platform, called E-GMP. In particular, the modules will power the Kia EV6. Mr. Sang-Cheol Shin, Inverter Engineering Design Team at Hyundai Motor Group said “ST’s SiC-MOSFET based power modules are the right choice for our traction inverters, enabling longer range. The cooperation between our two companies has realized a significant step towards more sustainable electric vehicles, leveraging ST’s continuous technological investment to be the leading semiconductor actor in the electrification revolution,”

ST has already supplied STPOWER SiC devices for more than three million mass-produced passenger cars worldwide. Compared to conventional silicon power semiconductors, smaller SiC devices can handle higher operating voltages that allow faster charging and superior vehicle dynamics. Energy efficiency is also increased, which boosts driving range, and reliability can be extended. SiC is gaining mass adoption in multiple EV systems such as the DC-DC converter, traction inverter, and on-board chargers (OBC) with bi-directional operation ready for vehicle-to-grid power transfer.

ST’s SiC strategy, as an integrated device manufacturer (IDM), ensures quality and security of supply to serve carmakers’ strategies for electrification. With the recently announced fully integrated SiC substrate manufacturing facility in Catania, expected to start production in 2023, ST is moving quickly to support the rapid market transition towards e-mobility.