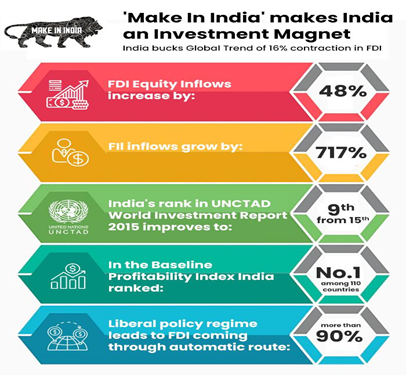

There is a steady impetus from the government to boost the manufacturing output, which today contributes almost 14.4% of the current GDP. Schemes such as ‘Make in India’, Atmanirbhar Bharat and Vocal for local have contributed positively to the manufacturing sector.

The national manufacturing policy aims to increase the GDP contribution of the manufacturing sector to 25% by the year 2025. PLI scheme for manufacturing is a key scheme under this policy. This has encouraged large industries in sectors such as electronics, mobile manufacturing, telecommunications, pharmaceuticals etc., to avail the benefits and setup units under this scheme. Each of these large industries has helped 100s of MSMEs set up as ancillary units and suppliers to these large industries.

Other contributing factors have been China plus one policy of businesses looking to diversify their manufacturing units outside China. India has emerged as a key go-to-market for companies looking to move out of China and set up alternative manufacturing destinations. This process has taken pace post-Covid due to large-scale supply chain disruptions and lack of transparency in Chinese policies.

Top 5 fastest growing sectors in the manufacturing industry:

- Traditionally, India has been seen as an agricultural community, and even today, almost 60% of the population is dependent on agriculture as their primary occupation. Today India ranks as the largest producer of many food products such as pulses, milk, rice etc. Food Processing is one of India’s largest and fastest-growing opportunities. With a projected growth rate of 9% p.a., the market is set to be about $535bn by 2025-26. So naturally, the potential for the food processing industry is significant, with a massive market in India and for export as well, especially in the middle east, southeast Asia and the African region. Products can range from vegetable and fruit processing, millet processing, meat and seafood processing, protein-based plant meats, immunity-based beverages, nutraceuticals and a host of other similar products that have seen great demand in the last five years.

- Next, the defence and aerospace sector has seen large investments and the decision of the Indian Defence sector to indigenise most of the products in India itself has seen vast opportunities for large corporations and in turn for MSME industries to become suppliers and vendors to these large units. Make in India and the Positive Indigenization List of 209 items released by the Defence PSUs have enticed many new entrants in this sector. A further list of 2851 items and 107 Line replaceable units will have an embargo on import shortly. The aerospace sector has also seen many activities in drone manufacturing wherein drones are being tested to enhance medical delivery, surveillance, crop monitoring and commercial last-mile delivery. There is also enormous scope for MRO of commercial and defence aircraft in India. Both these, put together by itself, is a market opportunity of $83bn by 2025-26.

- The third opportunity is in the pharmaceutical sector which has seen a growth of almost 17.3% over the last three years and is projected to be almost $90bn by 2025-26. The three main factors for this exponential growth have been the impact of Covid, the subsequent disruption of the supply chain in China and hence the need for the production of drugs and APIs in India, and the huge government support for production boost with targeted PLI schemes for bulk drug manufacturing, KSM and drug intermediaries and manufacturing of medical devices.

- The fourth sector of interest in India is the chemicals sector, where the demand for speciality chemicals and agrochemicals will be around $153bn by 2025-26. The China import embargo has further hastened the progress of new plant setups in the chemical sector. The sector comprises more than 80000 individual products, prompting an FDI inflow of $20bn in the last two years. The entire industry, except for a few hazardous chemicals, has been de-licensed, due to which it’s expected that the whole sector will contribute $300bn by 2025-26. Supply chain disruptions in China have prompted global chemical giants to look at setting up units in India.

- Finally, there are many trending and new ideas in the manufacturing sector comprising Electric vehicle and battery manufacturing opportunities, Ethanol manufacturing, ancillary units for semiconductor manufacturing plants, bio-degradable packaging material, bio CNG and biofuel units, essential and edible oil units etc. These are all sunrise sectors that have immense potential for the next 10-15 years with good government support.

Advantages of starting a manufacturing industry in India:

With a significant impetus on thinking globally and acting locally, the manufacturing sector is in for a complete turnaround. Indigenising several sectors, such as railways, defence, pharma etc., has opened up immense opportunities in this sector. Some of the key factors to consider for any entrepreneur in the manufacturing sector are:

❖ Availability of young and skilled workforce

❖ Cost advantage leading to lower manufacturing costs

❖ Family-run businesses are opening up as the second generation of entrepreneurs are looking to implement time and money in improving processes and quality

❖ Huge domestic market

❖ Excellent government support

❖ Free trade agreements with strategic countries encourage FDI from other countries who want to manufacture in India and export to their home countries

❖ Manufacturing has traditionally been a forte of the MSME sector, hence good flexibility and easy-to-implement new technologies and adapt to new market requirements

Government’s Policy initiatives to shape India into a global manufacturing hub:

The government has many schemes for the MSMEs and in general for employment generation such as the PMEGP(Prime Minister employment generation program), Easy credit availability through the CGTMSE (Credit Guarantee for micro and small enterprises)scheme, Upgradation of existing MSMEs through the RAMP (Raising and accelerating MSME performance) program, skill development through the ESDP(Employee skill development program), PMS( procurement and marketing support), Digital MSME and MPDA(Market promotion and development) scheme for marketing and a host of such schemes. The PLI schemes for the manufacturing sector cover about 14 sectors and have an outlay of Rs.2 lakh crore, which is easily the largest government scheme to date targeting the manufacturing sector to date.

The new schemes have seen a lot of private players taking a renewed interest in India which is evident from the recent deals that manufacturing majors such as the Vedanta Foxconn semiconductor plant, the Tata airbus manufacturing unit, Titan industries etc. have signed up deals to setup mega scale factories. The government has also invested heavily in training facilities to train/retrain skilled workforce through the Assistance to Training institutes scheme and ESDP scheme. MOFPI (Ministry of Food processing industries) also has 32 unique schemes under its ministry to promote the processing of locally available raw materials in the F&B sector. Apart from the Central government schemes, each state has rolled out the red carpet to new manufacturing industries with additional incentives and single-window approval schemes.

Importance of the manufacturing sector in India’s economic growth

The government has begun to recognise the importance of the MSME sector as it provides employment to 11 crore people and contributes to almost 45% of the total manufacturing output of India. This has led to the modernisation of existing units and rapid expansion in new sectors of the manufacturing industry. Adoption of technologies under Industry 4.0, IIoT, digitalisation of MSMEs and implementation of robotics have been some of the latest trends which have seen new capital being deployed and in turn, helped in competing in the global markets with high quality and affordably priced products from the Indian manufacturing units. With the government schemes and grants to promote manufacturing and, in turn improve the employment opportunities in Tier 2 and 3 cities across India, this period can indeed be called the Era of manufacturing in India.