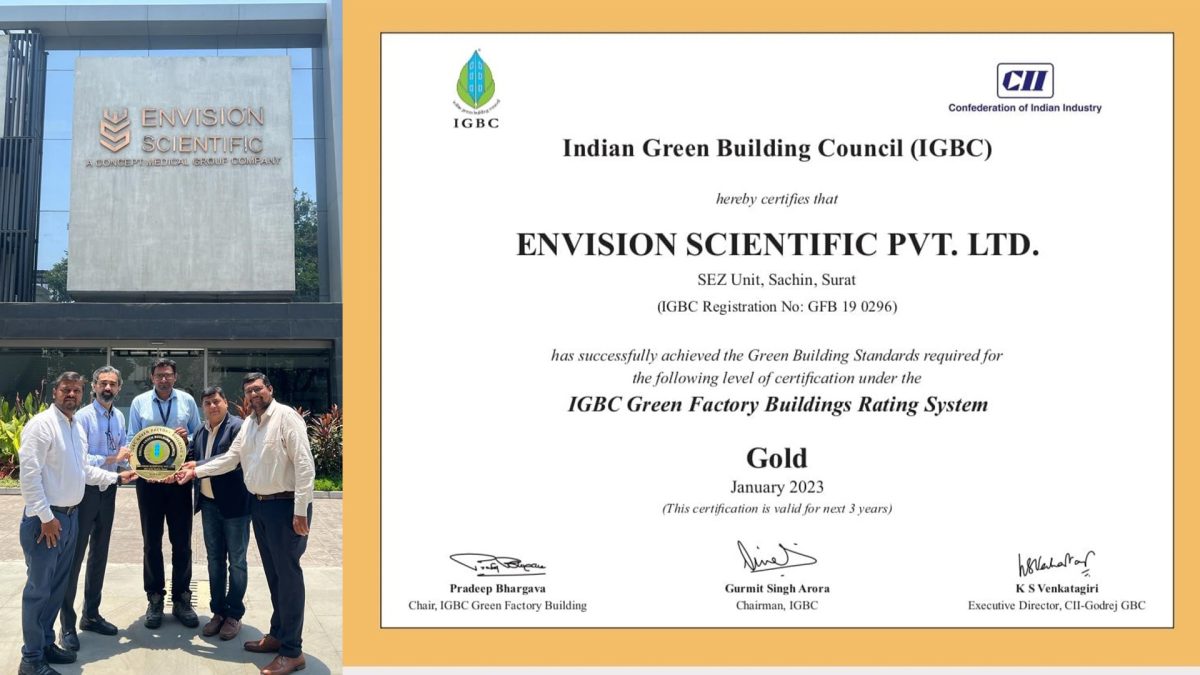

Indian Green Building Council (IGBC) has granted the gold certification for the green factory building of Envision Scientific Pvt. Ltd. (ESPL), the manufacturing arm of Concept Medical. This certification is a testimonial to the company’s dedication to incorporating sustainable practices and becoming environmentally responsible.

The IGBC green factory buildings programme is the first of its kind. It helps evaluates manufacturing facilities based on multiple criteria, including energy efficiency, water conservation, refuse management, and interior air quality.

ESPL is the first factory in the Surat Special Economic Zone (SEZ) to be certified as a green building. To achieve this feat, the company has taken several conscious steps to become energy efficient and reduce its environmental burden such as the implementation of solar panels on its own property, energy efficiency development projects, and tree-planting campaigns and much more.

The Envision Scientific’s SurSEZ manufacturing facility utilises energy-saving equipment, lighting systems, and solar power. Rainwater harvesting and water-efficient fixtures have been deployed to reduce water consumption. Additionally, the company has taken painstaking measures for recycling and correct disposal of waste hence promoting proper waste management in the factory. Additionally, enhanced ventilation and low-emission materials have been used indoors to promote the health and well-being of occupants.

Commenting on the achievement, Parth Doshi, Director, of Concept Medical & ESPL, said that the company’s manufacturing facility is playing a significant role in guaranteeing a minimal carbon footprint by implementing innovative and effective measures. These steps help in achieving goals without negatively impacting the environment.

Other green imitates taken up by ESPL include tree plantation drives around the factory, charging stations for 2-wheelers and 4-wheelers, ETP and STP plants and measures to reduce the use of single-use plastic for packaging.