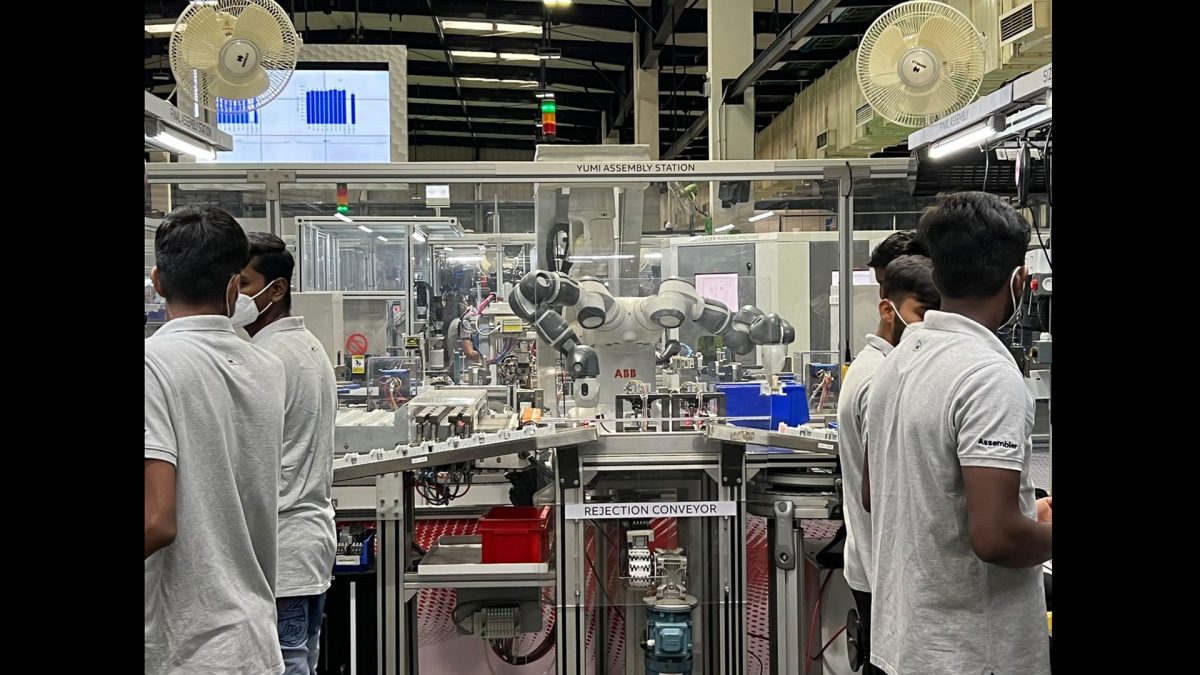

ABB India has expanded and upgraded its Smart Power factory in Nelamangala, Bengaluru, to meet the strong demand growth for its Smart Power solutions and energy management technologies with one of the first Industry 5.0 production processes. The smart facility harnesses advanced collaborative robotics technology for better human-machine interface, artificial intelligence (AI) and advanced digitalization technologies to create a sophisticated, automated, and flexible future-ready factory.

“The upgrades and expansion at the Bangalore factory make it one of our most advanced production facilities in the world. The adoption of exciting new Industry 5.0 technologies makes this an ideal home for the production, testing, and supply of ABB Smart Power’s technologies. The Smart Power team are the ideal partners for customers pursuing higher standards of safety, reliability, and energy efficiency in their operations,” says Giampiero Frisio, President, Smart Power Division, ABB Group.

This first-of-its-kind facility manufactures, tests, and supplies ABB Smart Power’s complete range of low voltage power equipment and energy management technologies to meet demand from the industry for increased reliability and energy savings. It caters to the increasing demand across sectors, including commercial and residential buildings, infrastructure, utility and renewable energy systems of solar, wind and many others where electricity is consumed.

Spanning over 8,400 sqm, the ABB Smart Power factory links equipment such as robots, motors, and drives to the Internet of Things (IoT). The connected factory software highlights process optimization opportunities and schedules predictive maintenance to maximize productivity and efficiency. This resulted in enhanced productivity of 40% in the same space, with an energy efficiency of 15%.

“Through our own digital transformation at this facility, we will be able to demonstrate the benefits of adopting smart solutions directly to our customers. We believe that this will encourage the shift towards digital and sustainable manufacturing in India,” said Kiran Dutt, President, Electrification Business, ABB India Ltd.

This facility also houses numerous robot types with combined autonomous test cells for different product variants. Enabling last mile manufacturing competitiveness, a Metrology Lab ensures standardization in measurement, calibration, and inspection to match the highest design specifications and product quality standards. A Test Lab in the facility performs rigorous endurance tests of products manufactured for conformance.