The automation of society and technological breakthroughs have had a substantial impact on the workplace environment, and the print industry isn’t left behind. Enterprises, especially in the manufacturing segment, are now jumping on the bandwagon by creating a workflow, which falls in line with the future of printing.

While most organisations are aware of their transformational technology requirements, the deterrent to implementing is an absence of clear visibility of ROI by the CXO, hampering his ability to make an intelligent decision. Further, different workflow automation solutions providers approach manufacturing companies with a limited problem solution. Due to this narrow approach, it becomes difficult for a CXO to assess the impact of a technological change or transformation at various levels in the organisation.

So, the planning needs to change from “what manufacturers have to do” to “how,” and that’s where technology and software solutions can create a revolution. By utilising digital technology, manufacturers can transform their infrastructures to automate business-critical processes to cut out paper-based inefficiencies, improving productivity, innovation, and global collaboration.

Some of the trends that are here to stay and will help the manufacturers rethink and redesign processes are 3D printing, Artificial intelligence (AI), Internet of Things (IoT), analytics, and automation.

Adapting Innovation – IWS, 3D Printing and IoT

A prominent move that’s happening in the printing industry is the adoption of Intelligent Workplace Services (IWS). This change will reduce the complications of on-premise printing management as all the print jobs gets submitted to a virtual print server and ensures elimination of on-premises servers reducing the maintenance & improving efficiency.

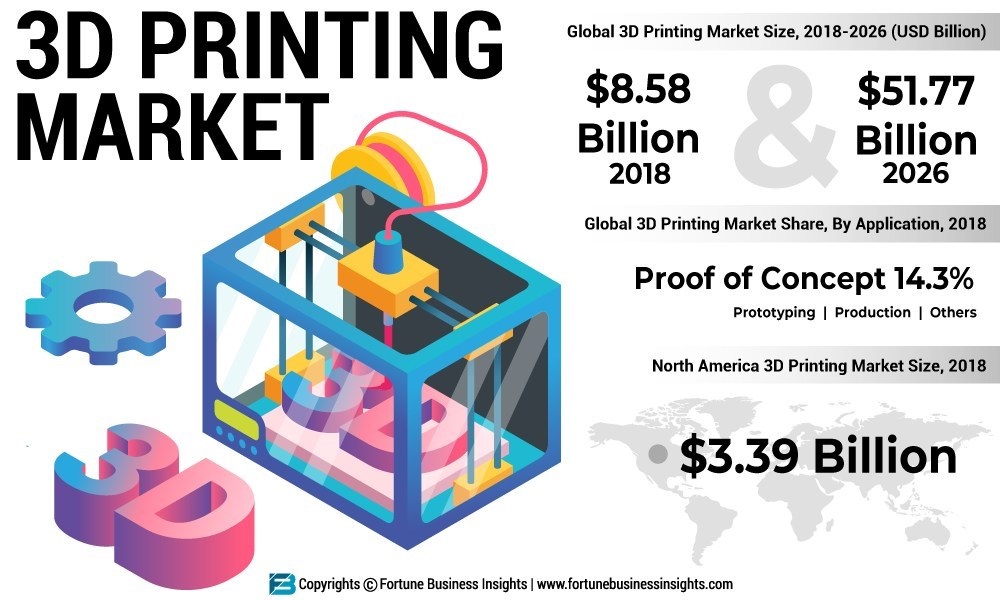

The Indian manufacturing industry is adopting 3D printing technology at an early stage to capture a significant market share through rapid prototyping. Another benefit is that one can postpone the physical production and associated costs with it.

IoT technology has the power to make gaping changes to the print industry, which is rapidly adapting to the massive spread of mobile devices and their various platforms of connectivity.

By adding IoT-accessible sensors and networking technologies to printer hardware that already uses cloud connectivity and improved document processing capabilities and intelligence, businesses can gain valuable real-time insight into print usage.

With an entire suite of end-to-end solutions available for the complete value chain, manufacturing companies can optimise their operations and improve productivity manifold.

Supply Chain, Warehouse & Logistics

Manufacturing companies must automate the workflows in the entire supply chain operations by providing solutions for improving inventory visibility, material movement and storage utilisation, etc. Barcode printing solutions utilise the precision and low operating costs of printers and multifunction devices to print barcodes and thus improve productivity and optimise workflows. Logistics services are managed by automated and integrated order processing and inventory control systems, and once on receipt, orders are shipped within 24 hours. In other words, logistic systems need a robust system to accurately ship products anywhere in the world. The solutions further provide easy archival, distribution, and retrieval facility to clients.

Research and Development Testing

Another very critical department in any organisation’s value chain is the R&D department, helping them drive change & have a competitive edge over others with a clear foresight of the future problems and their solution. Hence, having better delivery, improved timelines with pre-configured workflows & improve engagement and collaboration from key stakeholders at every step in R&D is exceptionally critical. Manufacturers can automate the most complex part of market testing by shifting it on a secure online portal, which can result in a successful product outcome and delivery involving suppliers and customers, also helping them save costs at different stages of R&D testing.

Quality & Operations

Quality act as a differentiator between you and your competitors & understand the environment where it is essential to keep innovating and sense the pulse of the market. In manufacturing flow, access to the right set of organisation processes and procedures by the key individual helps in delivering the desired outcome. Hence, if the information is located at a centralised server, the team can deliver quality services to the customers. With automation, organisations can improve their continuous process, share real-time feedback on errors, and rectifying them at the processing stage. This allows standardising processes to promote safety, efficiency, and better productivity across the organisation with consistency. With sophisticated processes and integrated systems, you can also improve client MRO revenues by building a world-class MRO base.

Beyond the business processes, manufacturers can also opt for cross-industry solutions to bring down expenses related to the management of human resources, finance, operations, mailroom, and much more. These are some of the critical areas where manufacturers can reap the benefits of automation and improve their overall work efficiency and opt for a complete digital transformation with minimised cost.

The article is written by Ritesh Gandotra, Director, Xerox Business Services.