The case study is about MG Motor India using MindSphere and Plant Simulation IoT data analytics to identify the root cause of production loss. Using the MindSphere visualization application, the automotive manufacturer increased throughput by 15 per cent in the paint shop.

Addressing the bottlenecks in paint shop operations

In 1924, Morris Garages vehicles were founded in the United Kingdom (UK). MG Motor India (MGI) is a SAIC Motor Corporation Limited subsidiary specialising in automotive manufacturing.

Most operations are located primarily in India at their plant in Halol. The company manufactures automotive parts and vehicles. There are many moving parts in an automotive assembly line, including a paint shop that focuses on surface treatments to the body of the vehicle and pre-treatment and electrolytic deposition (PTED) stations. Streamlining PTED paint shop procedures has been a significant bottleneck for the MGI plant team over the past few years.

With legacy automation systems in operation for over 20 years, the team couldn’t use existing system such as programmable logic controllers (PLCs) and Andon Systems to disclose or suggest information on productivity development prospects.

They couldn’t study processes aside from standard key performance indicators (KPIs) such as overall equipment effectiveness (OEE) or downtime data. The systems in the paint shop did not provide reliable and accurate real-time performance data.

While they were able to pluck the low-hanging fruit using the existing methods and technologies, the team needed enhanced analytics to eliminate process bottlenecks. “The existing system did not provide the time needed to execute individual steps at each station such as wait, travel and idle time and they couldn’t capture the process time and store it retrospectively. We needed solution to fulfill the challenge and manage reliable accurate input data,” says Ravi Mittal, director of manufacturing for MG Motor India.

Leveraging MindSphere to connect the data and identify bottlenecks

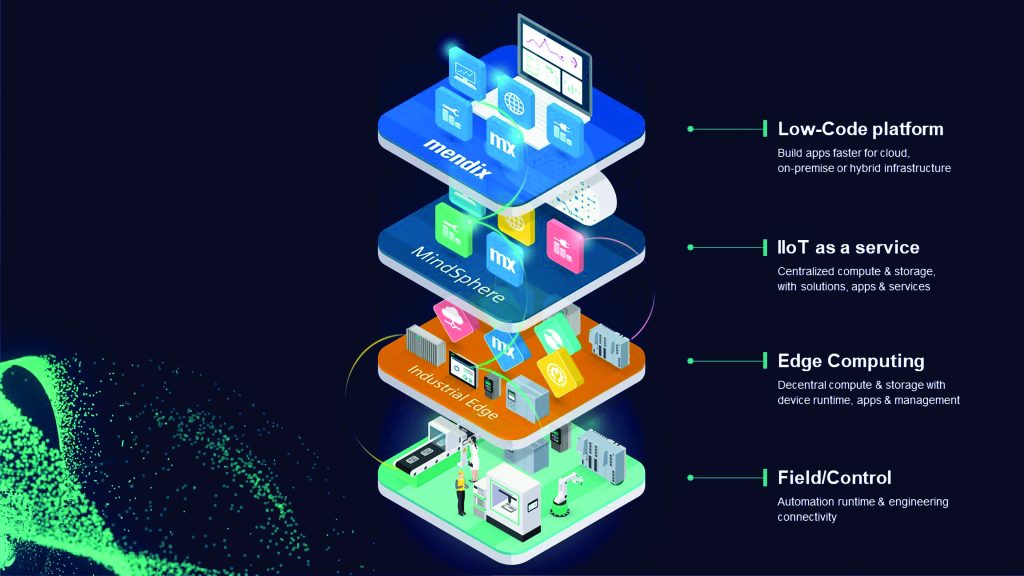

MGI adopted MindSphere®, the industrial IoT service solution from Siemens Digital Industries Software, and Plant Simulation in the Tecnomatix® portfolio to address this issue. MindSphere and Plant Simulation are part of the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services. MGI adopted these two software portfolios successfully, increasing throughput and production in PTED line.

Using the out-of-the-box (OOTB), MindSphere connectivity solution enabled MGI’s team to connect isolated assets and transfer the data to MindSphere using mobile communications (GSM) network.

All time series data from each step of the production process were uploaded into MindSphere to provide the basis for further data analysis. “We use the MindSphere application, Visual Flow Creator, to build our workflow to create rules, define KPIs and perform advanced analytics. It enables us to convert the raw time series data into meaningful information,” says Mittal.

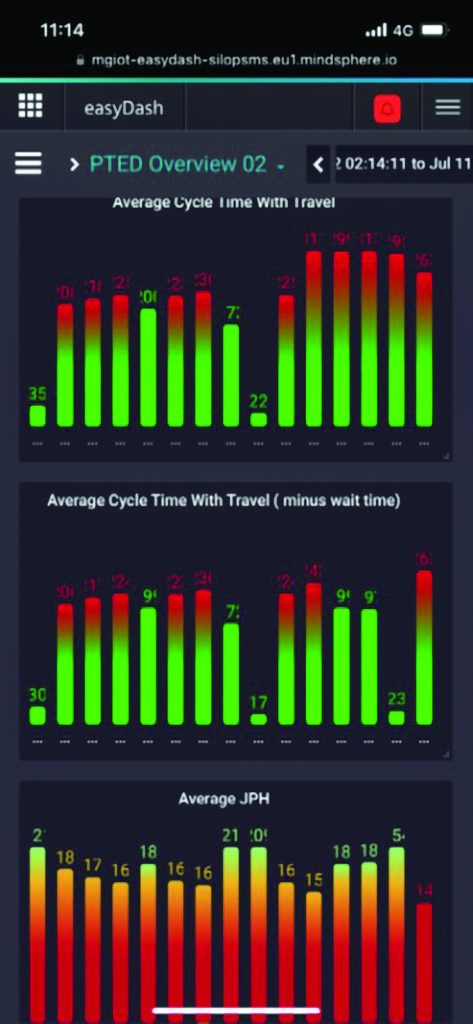

“Using another MindSphere application, easyDASH, enables us to create dashboards easily. We can monitor and visualize shop floor assets for optimization and performance management,” says Mittal.

“We use the dashboard’s colour feature to indicate whether important parameters such as JPH, cycle time, waiting and travel time stay within their target operating efficiencies. This provides us with a more cohesive vision of the current state of the process and allows us to make more effective decisions.”

Visualization and customized analytics powered by MindSphere capture the digital process data for micro steps and even store it on the cloud. This enables MGI to visualize and carry out the process’s strengths, weaknesses, opportunities and threats (SWOT) analysis. This helps the MGI team identify the root causes of the production losses and action to improve the net output.

Integrating MindSphere and Plant Simulation to optimize production throughout

“Once we collect real production data from the shop floor, we transfer the time series data from MindSphere to Plant Simulation, which enables us to use a digital twin model to understand the root cause of a problem by replaying the production using the actual production data,“ says Mittal.

“Once we identify the problem, we make the required changes and verify the impact of the changes using the simulation with the actual production data, which more accurately shows any unintended effects or new constraints caused by these changes. After resolving these issues in the virtual digital twin model, we now have the confidence to implement the changes to the production system.”

Using the industrial internet of things (IIoT) paired with plant simulation forms the closed-loop comprehensive digital twin, which enables MGI to use real production data to continuously optimize throughout.

Improving paint shop performance

“Siemens has the ability to combine three domains: operational technology, IIoT technology and system simulation, all connected in near real-time, which helps us increase throughput in PTED line by 15 per cent,” says Mittal.

Collaborating with Siemens to continue the digital transformation journey

“MGI is constantly evolving to meet rapidly changing requirements and provide innovative services by collaborating with ecosystem partners,” says Mittal. “Our collaboration with Siemens is focused on industrial digitalization and intelligent manufacturing. With MindSphere, we hope to boost productivity and improve production efficiency by leveraging advanced IoT data analytics to quickly monitor essential assets and systems in real-time and minimize unexpected downtime. We are pleased to partner with Siemens and we aim to adopt software technology throughout the general assembly to further transform operations.”