Electric vehicles (EVs) are gaining popularity due to their environmental friendliness, energy efficiency, and lower operating costs. However, EVs come with unique challenges, one of which is the management of their batteries. Different types of batteries are used to power electric vehicles, and deciding which battery is best depends on its energy storage efficiency, production costs, constructive characteristics, safety, and lifespan.

“It is true that EVs have been gaining popularity in recent years as charging infrastructure improves and battery technology becomes more efficient. According to IEA, the figure of electric cars on the road could reach 145 million by 2030. Furthermore, main automakers have been investing a lot in EV machinery and introducing the latest electric models to their lineups. Overall, the transition to EV is well in progress, and it seems likely to continue as more with the environmental and economic benefits of electric vehicles, shares Dr Abhishek Choubey, Head- Industry Institute Partnership Cell (IIPC) & Associate Professor, Department of Mechanical Engineering, Sagar Institute of Science Technology & Research (SISTec), Bhopal.

Lithium-ion batteries are the most utilized technology in electric cars. EVs run on high voltage lithium-Ion battery packs. Lithium-ion batteries have higher energy density (100-265wh/kg) compared to other battery chemistries. They pose a risk of fire under unusual circumstances. It is crucial to operate electric vehicles in pre-defined safety limits to ensure the safety of the user as well as the vehicle.

“BMS is a critical component of every EV today as it is needed to manage battery performance, adjust power output on the go, and facilitate safe charging. At Lohum, we link BMS to our smartphone app and rapidly determine accurate battery residual value to unlock new 2nd life applications for used EV batteries, such as off-grid EV charging stations, ESS and UPS systems, and more,” explains Rajat Verma, CEO & Founder, Lohum Cleantech.

Lithium-ion batteries can have slight variations in their capacity and resistance, which can lead to imbalances in the pack over time. If the cells become too imbalanced, it can lead to reduced performance and safety issues, such as overcharging or overheating. As a result, it becomes a key component of EV usage that must be constantly monitored and controlled. This necessitates the use of an EV Battery Management System (BMS).

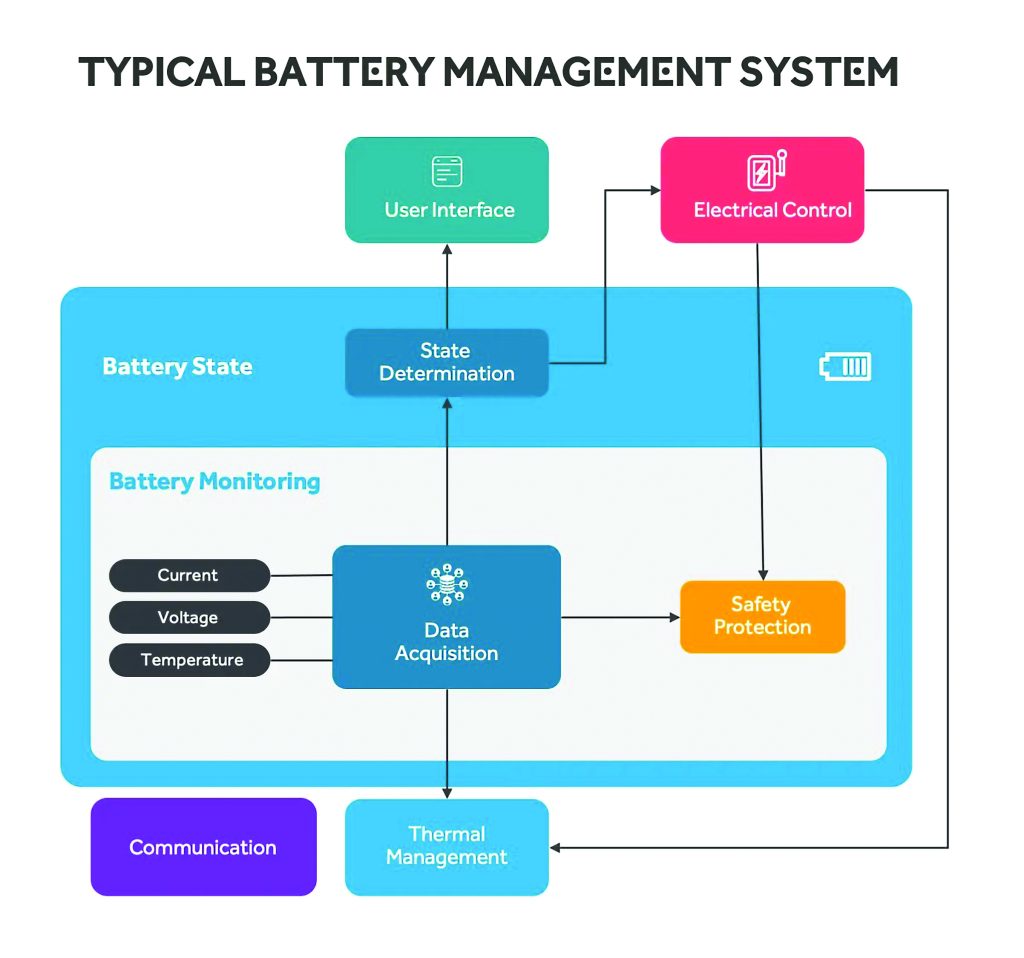

A BMS, which manages the electronics of a rechargeable battery, whether a cell or a battery pack, thus becomes a crucial factor in ensuring electric vehicle safety. It safeguards both the user and the battery by ensuring that the cell operates within its safe operating parameters. It acts as the brain of the battery, ensuring that it operates within safe limits and maximizes its lifespan. It is primarily designed to safeguard the battery and prevent any actions that may exceed its safety threshold. BMS has various functions, including monitoring battery temperature, state of charge (SoC), state of health (SoH), and cell voltage balancing.

One of the primary concerns with EV batteries is overheating, which can lead to thermal runaway, a dangerous situation where the battery rapidly heats up and releases gas, potentially causing a fire or explosion. Lithium-ion batteries are sensitive to temperature, and high temperatures can lead to reduced performance and accelerated degradation. Therefore, the BMS must ensure the battery stays within a safe temperature range, even under high loads or extreme environmental conditions. These systems can either be passive or active, and the cooling medium can either be a non-corrosive liquid, air, or some form of phase change. Using air as a coolant is the simplest way to control battery temperatures.

Lithium-ion batteries degrade over time due to a variety of factors, including cycling (charging and discharging), high temperatures, and aging. In addition to managing the battery’s performance and safety, the BMS also plays a role in extending its lifespan. BMS monitors the SoC and SoH of the battery. SoC is the measure of how much charge the battery has, while SoH is the measure of how much capacity the battery has lost over time. BMS ensures that the battery is not overcharged or discharged beyond safe limits, preventing damage to the battery and maintaining its longevity.

Cell voltage balancing is also a vital function of BMS. The cells in an EV battery pack can have different voltages, leading to an imbalance that can reduce the battery’s performance and lifespan. BMS ensures that the cells are balanced by redistributing charge between them. BMS also communicates with other systems in the EV, such as the motor controller and the charging system, to ensure that they operate within safe limits and are compatible with the battery.

So what are the design considerations for a BMS? Dr Choubey shares in simple points:

- Security: The security of the battery and the adjoining equipment must be the top priority. The BMS should monitor the battery parameters abnormalities and take suitable action to prevent over charging and overheating.

- Accuracy: The BMS should provide accurate information about the state of the battery, including its voltage, current, and temperature. The accuracy of the measurements is crucial for the proper operation of the battery and the optimization of its performance.

- Scalability: The BMS should be designed to hold different battery chemistries, sizes, and configurations.

- Reliability: The BMS should be designed for long-term reliability and minimal maintenance.

- Communication: The BMS should be able to communicate with other systems in the vehicle to manage the charging and discharging of the battery.

- Power consumption: The BMS should consume minimal power to maximize the energy efficiency of the battery. The BMS should be designed to run on low power modes when the battery is not in use.

- Cost: The BMS should be cost-effective, and the cost of the BMS should not add significant cost to the overall system.

The battery management system, thus is a critical component of electric vehicles, responsible for ensuring safe and efficient operation while maximizing the battery’s lifespan. By carefully monitoring and controlling the battery’s state of charge, temperature, and other parameters, the BMS helps to optimize performance and reduce the risk of damage or degradation. As EV technology continues to advance, the role of the BMS will only become more important in enabling reliable and sustainable transportation.

Sources: Cyient, Loconav, ARAI