Stratasys, a leader in polymer 3D printing solutions, will showcase additive manufacturing solutions for every stage of the product value chain at Formnext (15-18 November, Frankfurt am Main, Germany) under the theme “Let’s Talk Manufacturing”. It will include an expanding portfolio of materials as well as the P3 Automated Production Cell, a demonstration project to improve the efficiency of operating fleets of Origin® One 3D printers.

Making the future of manufacturing a reality

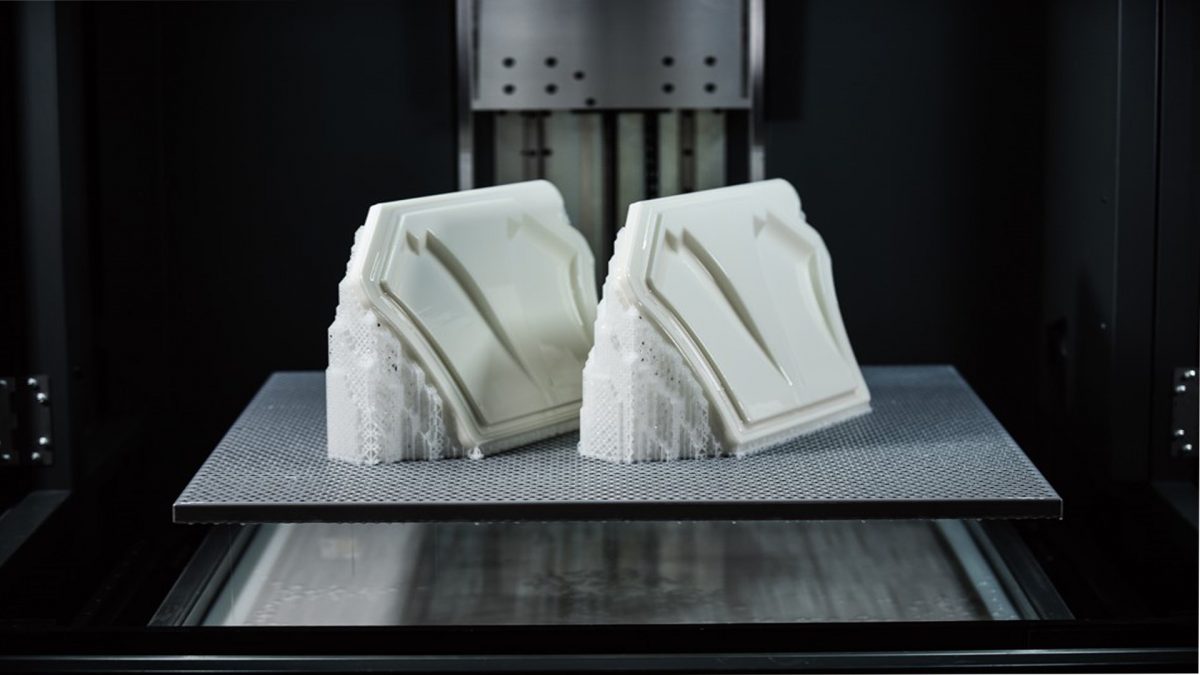

The demonstration project production cell operating in the Stratasys stand is designed to automate the movement of parts between multiple 3D printers and post-processing equipment for cleaning, drying and curing. The goal is to significantly reduce the labour resources required as 3D printing scales up on the factory floor.

Advancing Urban Mobility

Stratasys will also showcase its support for innovation in urban mobility with a new vehicle category in the booth. The working prototype was developed by Stratasys customer nFrontier using both 3D printing and traditional manufacturing.

Materials to drive production growth

With the goal of enabling manufacturing customers to address new applications with demanding requirements faster and more efficiently, Stratasys has continued to grow its materials ecosystem through new partnerships and third-party material options. Materials on show will include Stratasys Preferred and Validated materials for Stratasys 3D printers based on five different 3D printing technologies: stereolithography, SAF™, FDM®, P3™, and PolyJet™. These include materials provided by partners such as Arkema/Kimya, Victrex plc, and Covestro.

Andy Langfeld, President EMEA at Stratasys, said, “We continue to accelerate cutting-edge developments in additive manufacturing and advance our strategy of providing the best and most complete polymer 3D printing portfolio in the industry.”